1+N+1 HDI PCB: FastTurnPCB’s Expertise in BGA and SMT PCB Assembly

The demand for high-performance electronic devices continues to rise, requiring advanced PCB assembly techniques such as Ball Grid Array (BGA) and Surface Mount Technology (SMT). FastTurn PCB has positioned itself as a global leader in delivering precise, reliable, and efficient PCB assembly solutions, particularly for complex 1+N+1 hdi pcb designs. With decades of experience, state-of-the-art facilities, and a commitment to quality, FastTurnPCB provides electronics manufacturers with the expertise needed to produce high-density, high-performance PCBs for diverse applications.

The Importance of BGA and SMT Assembly

Modern electronic products are shrinking in size while increasing in functionality. This creates the need for sophisticated PCB assembly techniques like BGA and SMT to manage higher component density and improve electrical performance.

- BGA (Ball Grid Array): Offers improved electrical performance, better thermal management, and reliable connections for complex ICs.

- SMT (Surface Mount Technology): Allows compact and precise placement of components on the PCB surface, increasing assembly efficiency and reliability.

For electronics manufacturers working with 1+N+1 hdi pcb designs, mastering BGA and SMT assembly is crucial to achieving high-quality, reliable devices. FastTurnPCB’s expertise ensures consistent and precise assembly for all board types.

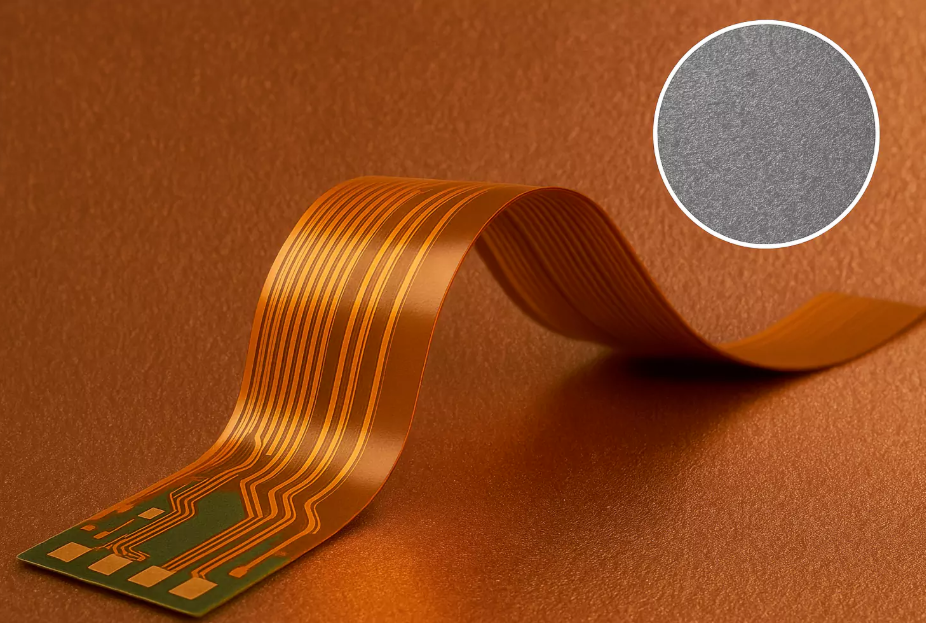

Advanced 1+N+1 HDI PCB Capabilities

High-density interconnect (HDI) PCBs, especially 1+N+1 layer constructions, are widely used in modern electronics due to their compact design and high routing density. FastTurnPCB excels in 1+N+1 HDI PCB fabrication and assembly, offering:

- Microvias and blind/buried vias for dense interconnections

- Fine-pitch component placement for precise SMT assembly

- Multilayer stackup optimization for signal integrity and thermal management

- High-density BGA placement for advanced ICs and processors

These capabilities allow manufacturers to achieve highly compact and high-performance PCB designs while maintaining reliability.

Comprehensive PCB Assembly Services

FastTurnPCB provides end-to-end assembly solutions for BGA, SMT, and mixed-technology PCBs. Their services include:

Surface Mount Technology (SMT) Assembly

FastTurnPCB utilizes high-precision pick-and-place machines capable of handling fine-pitch components, ICs, and BGAs. Their SMT assembly services ensure accurate placement, soldering, and inspection for 1+N+1 HDI PCB designs.

Ball Grid Array (BGA) Assembly

BGA components require advanced handling and soldering techniques due to their complexity. FastTurnPCB’s assembly lines feature controlled reflow ovens, precise alignment systems, and X-ray inspection to guarantee reliable connections for high-density packages.

Mixed Technology Assembly

Many industrial and consumer electronics designs combine SMT and through-hole components. FastTurnPCB offers mixed-technology assembly, integrating both methods for optimal mechanical strength and electrical performance.

Rigorous Quality Assurance

FastTurnPCB places quality at the core of their PCB assembly processes. For 1+N+1 HDI PCB designs, strict quality assurance is critical to ensure reliability and performance. Their testing protocols include:

- Automated Optical Inspection (AOI): Detects visual defects and placement issues

- X-ray Inspection: Verifies soldering quality and hidden joints under BGAs

- In-Circuit Testing (ICT): Ensures component functionality and correct placement

- Functional Testing: Simulates real-world operational conditions to confirm performance

These rigorous processes guarantee that every assembled PCB meets industry standards and client specifications.

See also: Streamlining Retail Operations With Advanced Technology

Rapid Prototyping and Production

FastTurnPCB supports both prototyping and full-scale production. Rapid prototyping enables manufacturers to validate 1+N+1 HDI PCB designs quickly, make adjustments, and reduce development cycles.

Their production workflow is optimized for speed without compromising quality, allowing electronics manufacturers to meet tight deadlines and accelerate time-to-market.

Turnkey PCB Solutions

FastTurnPCB provides complete turnkey solutions that include design review, component sourcing, assembly, testing, and logistics. By consolidating all services under one roof, they reduce the complexity and risk associated with working with multiple vendors.

Benefits include:

- Streamlined communication and project management

- Reduced production errors and delays

- Cost-effective and scalable solutions

- High-quality, reliable assembly for complex 1+N+1 HDI PCB designs

This turnkey approach makes FastTurnPCB an ideal partner for electronics manufacturers seeking reliable BGA and SMT assembly services.

Serving a Wide Range of Industries

FastTurnPCB’s expertise supports numerous sectors, each with specific requirements for reliability, precision, and performance:

- Consumer Electronics: Smartphones, wearables, tablets

- Medical Devices: Diagnostic tools, monitoring systems

- Automotive Electronics: ADAS systems, infotainment modules

- Industrial Automation: Robotics, PLCs, control boards

- Telecommunications: Network equipment, high-speed data devices

By combining 1+N+1 HDI PCB expertise with advanced BGA and SMT assembly, FastTurnPCB ensures manufacturers can meet the highest standards across all industries.

Engineering Support and Design Optimization

FastTurnPCB goes beyond assembly by offering engineering support to optimize designs for manufacturability and reliability. This includes:

- Design-for-Manufacturability (DFM) review

- Component placement optimization

- Thermal management recommendations

- Yield improvement strategies

Early collaboration with FastTurnPCB helps manufacturers reduce errors, improve production efficiency, and ensure optimal performance for 1+N+1 HDI PCB projects.

Global Reach and Logistics

FastTurnPCB supports electronics manufacturers worldwide with reliable logistics, inventory management, and shipping solutions. Their turnkey model ensures boards are delivered on time, fully tested, and ready for integration, regardless of the project scale.

Why Choose FastTurnPCB for BGA and SMT PCB Assembly?

Manufacturers trust FastTurnPCB for several reasons:

- Expertise in 1+N+1 HDI PCB fabrication and assembly

- Advanced BGA and SMT assembly capabilities

- Rapid prototyping and production with fast turnaround

- Rigorous quality assurance and testing protocols

- Turnkey services from design to delivery

- Global support and reliable logistics

- Cost-effective and scalable solutions

This combination of expertise, technology, and service excellence makes FastTurnPCB a top choice for electronics manufacturers worldwide.

Conclusion

BGA and SMT PCB assembly require precision, advanced technology, and reliable processes. FastTurn PCB delivers comprehensive solutions for 1+N+1 HDI PCB designs, supporting manufacturers in creating high-performance, reliable, and compact electronic products.

From prototyping to full-scale production, FastTurnPCB’s turnkey services, engineering expertise, and global support ensure that manufacturers can meet the demands of modern electronics with confidence.

For electronics manufacturers seeking a trusted partner for advanced PCB assembly, visit FastTurn PCB to explore their full range of services.