Differences Between Portable and Stationary Industrial Welding Fume Extractors

Maintaining safe air quality is a critical concern in industrial welding environments where fumes and fine particulates are continuously produced. These airborne contaminants can affect worker health, equipment performance, and overall productivity if not managed properly. Selecting the right air filtration approach plays a significant role in controlling exposure and maintaining compliance with safety expectations. Early in the evaluation process, an industrial welding fume extractor is often considered a foundational component of an effective air quality strategy. Understanding how portable and stationary systems differ helps facilities choose solutions that align with their operational needs and workspace layouts.

Understanding the Purpose of Industrial Fume Extraction

Industrial welding fume extractors are designed to capture harmful particles and gases at or near their source before they disperse into the work environment. Both portable and stationary systems share this core objective, but they differ significantly in how they achieve it. Factors such as facility size, welding volume, layout flexibility, and long-term production goals influence which option performs best.

While both system types support cleaner air and safer workspaces, their design and deployment impact efficiency, adaptability, and maintenance requirements. Recognizing these differences allows decision makers to align air quality solutions with daily operational demands.

Portable Industrial Welding Fume Extractors

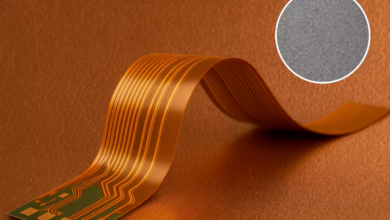

Portable fume extractors are designed for flexibility and mobility within dynamic work environments. These systems can be moved between workstations or repositioned as projects change. This adaptability is particularly valuable in facilities where welding locations vary or where space constraints limit permanent installations.

Portable units typically integrate compact filtration systems that provide effective source capture without requiring extensive infrastructure. Their design allows for targeted extraction, reducing the spread of fumes in localized areas. In many facilities, portable systems support temporary work zones or supplement existing ventilation where fixed systems are not practical. Despite their flexibility, portable units may have limitations in handling high-volume continuous welding operations. Their capacity is often best suited for intermittent use or smaller-scale production areas. Maintenance access is generally straightforward, supporting routine servicing without disrupting operations.

Stationary Industrial Welding Fume Extractors

Stationary systems are built for consistent, high-volume air filtration in fixed locations. These extractors are typically integrated into the facility layout and connected to ductwork that serves multiple workstations. Their design supports continuous operation and uniform air quality control across larger production spaces.

Because stationary systems handle higher airflow volumes, they are well-suited for facilities with consistent welding activity. Their centralized filtration allows for efficient contaminant removal and stable performance over extended periods. These systems often include advanced airflow management and multistage filtration to maintain effectiveness as particulate loads increase. Stationary extractors require more planning during installation but offer long-term reliability and scalability. Once integrated, they provide predictable performance and support consistent compliance with safety standards.

See also: Modern Advancements in Metal Bending Technology

Comparing Source Capture Effectiveness

Both portable and stationary systems emphasize source capture, but their effectiveness depends on placement and usage patterns. Portable units excel when positioned close to the welding source, offering immediate capture in flexible work zones. Stationary systems rely on strategically designed ducting and hoods to ensure fumes are captured before dispersal.

Understanding TEKA vs. traditional ventilation often highlights how modern source capture technologies outperform general air movement systems. This comparison reinforces the importance of capturing fumes directly at the source regardless of system type.

Conclusion

Portable and stationary industrial welding fume extractors each offer distinct advantages based on operational needs and facility design. Portable systems provide flexibility and targeted capture for dynamic environments, while stationary systems deliver consistent performance for high-volume production. Understanding these differences supports informed decision-making and helps facilities maintain safer air quality standards while optimizing productivity and long-term efficiency.