Parts Often Machined with Precision for the Aerospace and Medical Industries: are Machined Parts Really Needed for the Areas where Accuracy is Needed to ±0.001mm CNC Machined

In the aerospace and medical industries, every precision machined part is the defining criteria for critical areas such as safety, efficiency, and advancement. These components are needed for the aerospace and medical sectors which, with tolerances as close as ±0.001mm, are only possible with practical CNC machining. In order to meet the standards needed for exceptional equipment and quality control, the precision CNC machining manufacturers need to be capable of exceptional state of the art equipment.

Why it is important in aerospace and medicals, moreover, what challenges the business and companies face, is why it focuses around with specialized machining experts.

Focusing the Understanding Of the Need for Ultra Precision with the Critical Areas Of the Business Medical and Aerospace

Mechanical failure for surgeries is a big no. Taking into consideration the above and below, flight parts are subjected to and include, but are not limited to high spite, extreme temperature, and high load, the need with regards to aircrafts is the same. It is the same for medical surgical devices like, surgical instruments, parts of components which are driving to be avoided for foreign entities with regards to the human body.

There are two different sectors where the tolerance is ±0.001mm. It is needed to trust the CNC machining manufacturing to be below board, midway, and above board. An industry that you can trust is a machined parts provider.

Additionally, these sectors have specific compliance obligations. Within aerospace, every component undergoes tracking, testing, and certification related to its airworthy status. In medicine, there are rigorous international benchmarks of biocompatibility, sterilization, and safety for medical-grade products. Precision machining guarantees that these stringent requirements are met.

How ±0.001mm Tolerance Is Achieved

Meeting these requirements of tight tolerances involves having a skilled operational team, appropriate machinery, and well-planned workflows. This goes beyond precision engineering to a system that is controlled, and with a deep-rooted scientific underpinning.

Some of these methods are:

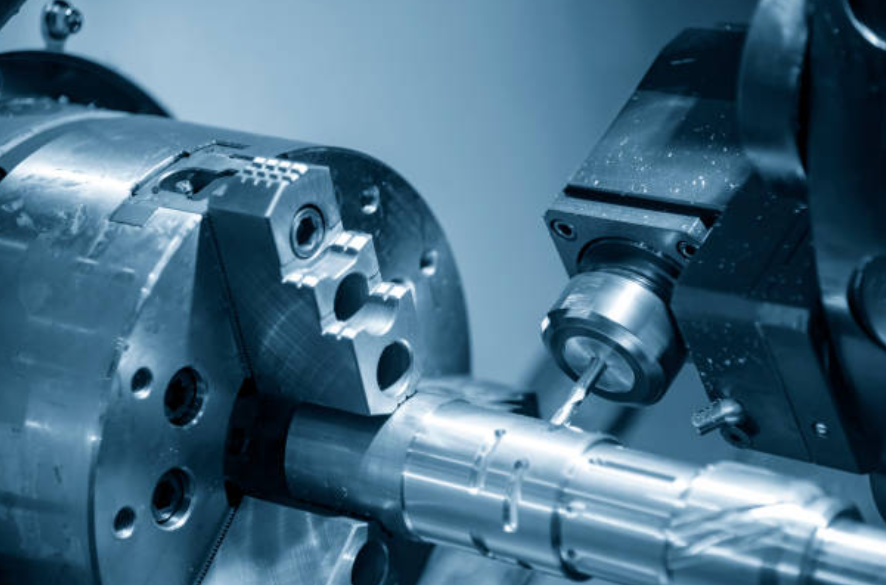

- Advanced CNC Technology – Multi-axis CNC machines, precision lathes, and grinding systems enhance dimensional accuracy for even the most intricate components.

- Environmental Control – The controlled machining area of temperature and humidity minimizes the chance of materials expanding and contracting.

- High-Quality Tooling – Production lots are consistently accurate due to the utilization of premium grade cutting tools and grinding wheels with sustaining precision over time, thus minimizing drift.

- Skilled Engineering Teams – Adjustments are made in real-time with the aid of seasoned engineers that constantly oversee machining values.

- Rigorous Inspection – At every stage of production, optical measuring systems, and CMM check the components for specified tolerances.

- Process Documentation – In order to maintain repeatability for similar prospective projects, every phase of production is meticulously documented.

Employing such techniques enables manufacturers to consistently create components within exact tolerances, even for materials that are quite challenging to machine.

See also: How Technology Is Revolutionizing Traditional Education

Aerospace Requirements for Precision Machined Parts

The degree to which the aerospace industry demands these engineers to adhere to standards is extreme such that each part is tested for functionality to avoid total failure during operations that include intense heat. Parts such as the following are examples of which machined tolerances of ±0.001mm are utilized on:

- Turbine Blades and Engine Components – These are the most critical parts of the aerospace machines and include the engines which all undergo rigid examinations post-manufacturing.

- Landing Gear Mechanisms – These components require an equally sophisticated system that enables the parts to function irrespective of the altitude of the fighter.

- Avionics Housings – These parts require considerable agility and need extreme precision which is once again oriented around machinists.

- Hydraulic System Components – The actuators are exposed to extreme temperatures which require efficient shielding.

Minor shifts in precision can create a myriad of issues and in fuel lack of fuel, but most importantly mechanical failure. Precision machined parts are vital to modern aircraft. As hydrocarbons are depleting, engineers need to manufacture aircraft that are more fuel efficient but require the use of expensive materials.

Medical Precision Machined Parts and Biocompatibility

Just like in aerospace, lesser parts are required for redundant features. Parts are required for extreme precision as the components are required to undergo extreme functions such as torsion and are required to follow a rigid criteria of in vivo regulations such as biocompatibility and hygiene.

Examples include:

- Surgical Tools – Precision instruments needed for ultra-minimally invasive surgeries that sharpen precision as ultra-sculpted and ultra-slim precision blades as protective coverings for geo-hyper layered inner tissues.

- Prosthetics and Implants – Measured and shaped prosthetic parts that ensure flawless and snug placement in the treated area for ease of mobility, prevention of discomfort, movement, long-life reliability, and chronic resilience.

- Diagnostic Equipment – For imaging and testing devices that need measurement devices, stable rigid frames and parts must be created and precisely profiled.

- Micro-Machined Devices – Tiny parts for medical sensors, catheters, and endoscopic tools which operate in highly tightly constrained spaces.

In this case, the precision of machining impacts the patient’s health. Any errors in machining could lead to safety, discomfort, or diagnostics errors. In some situations, precision tolerances must be more stringent than ±0.001mm.

The Issues in Obtaining Precision of ±0.001mm

The precision must be consistent maintained, which on the contrary to what was just stated, is still a challenge because of these reasons:

- Material Properties – Some materials require advanced compensating procedures for their expansion, contraction and shape changing due to heating and pressing.

- Tool Wear – Routine replacement and inspection is sometimes necessary for tools due to the need to ensure accuracy, whilst their tiny scratches start to add more and more.

- Process Stability – Long production runs require constant and stable fields as well as unchanging conditions.

- Skilled Labor – Collecting and using high-precision equipment requires a specific type of expertise.

Only a small percentage of facilities dedicated to machining are around the globe and possess the requisite skills and infrastructure to consistently attain such levels of precision.

Choosing the Right Precision CNC Machining Partner for B2B Projects

The choice of partners when it comes to doing precision CNC machining services greatly matters in achieving performance and dependability. Suppliers can be evaluated on the following criteria:

- Experience in Critical Industries – Successfully delivered aerospace and medical work.

- Technical Capabilities – Possesses the capacity to achieve complex parts with tolerances of ±0.001mm.

- Material Expertise – Knowledge of high-grade metals, ceramics, and polymer composites.

- Custom Prototyping Services – Ability to deliver fast and accurate prototypes for validation and testing before going to mass production.

- Quality Management Systems – Acclaimed for meeting international compliance in quality assurance and quality control benchmarks, and on traceability.

- After-Sales Support – Well-defined processes on communication and warranty, including defect and resolution processes.

B2B buyers get to enjoy consistent quality and faster lead times, with improved design flexility with dependable partners, without承担 production risks.

Your Consideration Concerning Precision Parts

Within the healthcare and aerospace sectors, precision machined parts are not just individual parts; they are critical components that protect lives and enable innovations. Working with a professional precision CNC machining manufacturer helps businesses achieve the highest levels of accuracy, dependability, and efficiency in the industry.

Ultra-precision manufacturing investment is not about just satisfying requirements, it also involves maintaining confidence, upholding safety, and facilitating advancement in critical industries where failure is not an option. For businesses in the high-risk industries, the ideal machining vendor becomes more than a provider; it transforms into a critical partner to achieve exceptional engineering.