Selecting the Right Pneumatic Cylinder for Your Shop Floor

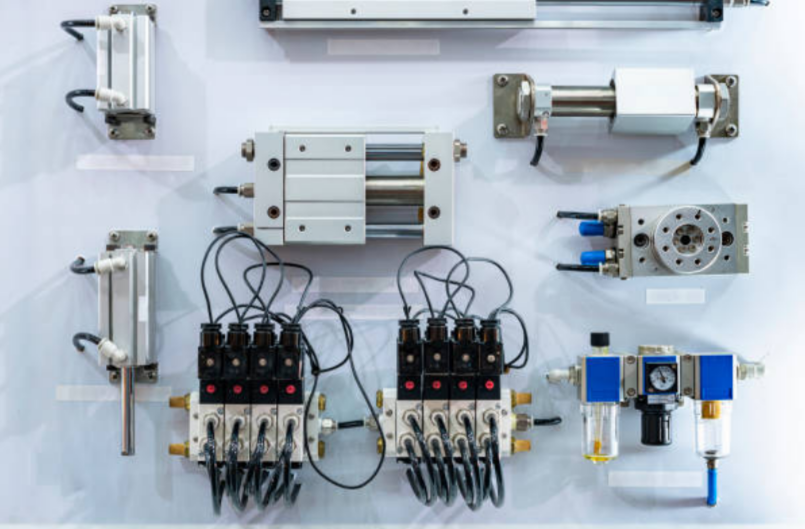

Pneumatic cylinders are the unsung heroes of factory automation. With nothing but compressed air for fuel, they create fast and repeatable motion in assembly lines, packaging machines, and even surgical robots. Yet the sheer number of cylinder styles on the market can trip up even seasoned engineers. Picking the right model means balancing stroke length, available space, and the weight of the load it has to push or pull.

Buying teams and system builders can simplify the task by leaning on a vendor like your neighborhood Omchele automation parts dealer. These suppliers offer everything from expert advice to a stock pile massive enough to scale with your project. The guide that follows lays out the most common pneumatic cylinders and pairs each one with a real-world job so B2B buyers can make decisions that stick.

Single-Acting and Double-Acting: The Basic Split

At the most basic level, cylinders fall into two camps: single-acting and double-acting. A single-acting unit uses air pressure to move in one direction and springs or gravity to return, while a double-acting version blasts air into both sides of the piston, allowing for power in both strokes.

Single-acting cylinders do one simple job very well. Air fills one side of the piston, pushes it out, then a spring pulls everything back. Because of that one-way push-pull, you’ll find them clamping, ejecting, or pressing sheet metal where the load only heads in one direction. The thing people like most? Fewer parts mean easy maintenance and a smaller project bill.

Double-acting cylinders flip the story entirely. Air boosts the piston out and then pushes it in again, giving you a push-pull powerhouse for demanding tasks. Picture pick-and-place arms or grips on a factory robot; those applications lean on the stronger, two-way control these cylinders deliver. When paired with reliable systems like a Kaeser air compressor, these cylinders repeat motions with consistent performance every cycle.

Compact cylinders answer the call when elbow room vanishes. Their bodies and strokes stay short without dropping the tons of force most plants need. Think cramped assembly lines or gadgets packing into only millimeters of clearance. A quick glance inside a modern electronics shop usually reveals several of these space-savers quietly getting the job done.

Even though they don’t take up much room, compact air cylinders pack a surprising punch. Plants love them because the gadgets fit into odd nooks yet keep grinding out work without breaking a sweat.

Manufacturers that push boxes down narrow conveyor lanes often turn to these little heroes. Partnering with an experienced Omchele automation parts supplier opens the door to cylinders that can be dressed up with custom mounts and tweaks to match any layout.

Rodless Cylinders: Maxing Out Stroke Without Adding Bulk

Rodless pneumatic cylinders ditch the old-style piston rod and slide instead on an internal rail. The head-on design chews up the same amount of real estate as a marker pen yet can shove a load the length of a pickup bed.

That extra reach is a game-changer in jobs like sliding doors, horizontal belt feeders, and clean-room transfer tables. Because nothing sticks out, contamination stands a much weaker chance, and stray forces that bend the barrel are kept in check.

When stroke length rules the design brief, most engineers circle rodless cylinders right away. Folks who want a custom tweak or two often find the search faster when they team up with an Omchele automation parts supplier that knows the market cold.

Guided Pneumatic Cylinders: Precision You Can Count On

Guided pneumatic cylinders are the go-to solution when machinery needs to deliver exact movements under heavy loads. Each cylinder pairs the piston with sturdy guide rods or sleek linear bearings, so rotation and twisting are pretty much ruled out.

Manufacturers slot these cylinders into all sorts of jobs, including

- Slamming metal sheets into shape at stamping presses

- Snapping components in or out of an assembly line

- Lifting crates while keeping everything balanced.

Because the extra guidance keeps parts square, plant managers notice a drop in the hours wasted on realigning equipment. Fields like electronics assembly and pharmaceutical packing rely on that same precision to stay on schedule.

Suppliers such as Omchele stock guided cylinders built for the long haul, giving high-volume lines the repeatability they depend on day after day.

Specialty Cylinder Types for One-Off Jobs

Not every project fits the cookie-cutter description, so engineers lean on several specialty pneumatic cylinder types

- Tandem Cylinders: Stack two pistons inside one barrel to crank up force without upsizing the bore.

- Through-Rod Cylinders: Let the rod poke out both ends, creating symmetrical motion perfect for odd-orientation tasks.

- Rotary Actuators: Flip compressed air into twisting torque, putting valves and light fixtures exactly where they belong.

Ready-Lift Pneumatics

Multi-Position Cylinders tuck two or three preset stops inside one neat package. You’ll spot them on assembly lines where parts need to pause and pivot without slowing everything else down.

A steady Omchele automation parts supplier makes certain that the cylinder you grab is rated for the load, the dust, and the red-tape inspectors who show up unannounced.

Real-World Matches

Knowing the theory behind a cylinder matters little if it never bolts to a machine, so here are some practical matches:

Welding Jigs in Car Shops rely on beefy double-acting or tandem cylinders that shrug off a truck’s worth of pressure.

Electronics Bench Work favors compact guided units that move, stop, and kiss a circuit board without cracking it.

Packaging Tracks get rodless and multi-position cylinders that shuffle, seal, and pop cartons open in one smooth breath.

Med-Tech Make Lines choose stainless single-acting tubes that stamp and assume a disinfected pose until the next cycle.

Pick the right style and the whole system burns less air, breaks down less often, and simply lasts longer. Partnering with an Omchele automation parts supplier keeps the ordering process fast and the quality good, no matter what floor of the factory you’re standing on.

Read Also: How Technology Is Revolutionizing Traditional Education

Conclusion

Picking the right pneumatic cylinder can feel like a small detail, but for machines that run on air, it is huge. Single-acting, double-acting, and rodless varieties each bring their own tricks, so knowing what each one does can keep production lines moving without hiccups. When pros on the shop floor understand those choices, downtime drops and confidence rises.

Team up with a dependable Omchele automation parts supplier and a lot of that heavy lifting disappears. The company stocks a broad mix of cylinders, offers custom builds when the standard stuff won’t cut it, and backs everything with on-the-spot tech help. That kind of one-stop support lets manufacturers grab the right cylinder, plug it in, and get back to making things run.