The Rise of Electric Actuated Ball Valves in Industrial Automation

For several years, Electric Actuated Ball Valves have played an important role in the automation of the process industries. Automation technologies have shown the value of these devices in streamlining control, improving efficiency, and enhancing the sustainability of industrial processes. This paper highlights the role of electric actuated ball valves in industrial automation and process streamlining and how companies, such as VINCER, are advancing this technology.

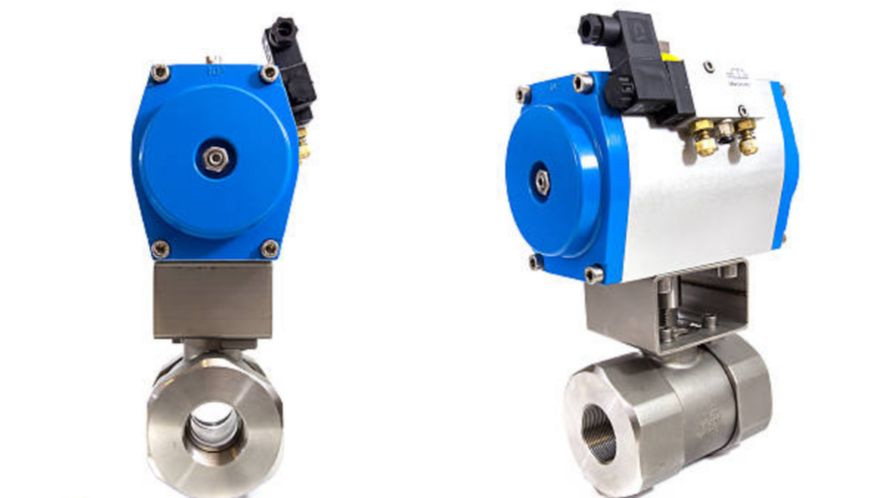

What Are Electric Actuated Ball Valves?

Electric actuated ball valves are hybrid devices that combine an electric motor actuator and a ball valve. Automation of valve actuators relieves manual control and enhances automation of industrial control systems. These systems provide remarkable control over the flow of a medium, and the valves can be rapidly actuated. The control systems of the valves integrate seamlessly into contemporary industrial automation control systems, thereby reducing manual intervention. VINCER is among the top quality electric actuated ball valves manufacturers to serve the needs of contemporary industrial systems.

In industries including chemical processing, oil and gas, and water treatment, electric actuated ball valves provide invaluable flow control.

Benefits of Electric Actuated Ball Valves in Automation

In automation systems, electric actuated ball valves present numerous benefits. Their accuracy and efficiency, coupled with reliability, contribute to their exceptional performance in modern automation systems.

Control and Precision

Electric actuated ball valves rank among the finest in flow control, allowing businesses to maintain a steady flow, a necessity in the pharmaceuticals, food processing, and chemical industries with respect to the safety and quality verification of the end product. With the most demanding applications, VINCER‘s electric actuated ball valves excel in precision flow control.

Minimal Maintenance Needs

When it comes to upkeep, electric actuated ball valves perform better than manual and pneumatic options. The electric actuators’ design features self-adjusting capabilities and reduced wear over time which lessens the frequency of upkeep significantly. The longer the maintenance interval, the less downtime needed, and the more the system optimizes. Predictive maintenance, made possible through remote monitoring, assures maintenance and system reliability within the entire industrial process. The valves manufactured by VINCER require minimal maintenance, which considerably prolongs their service life and reduces maintenance costs.

Efficiency of Energy

Electric actuators are much more energy efficient than pneumatic actuators. In this case, the actuator consumes less energy, and operating costs decrease, while gaining more control over the process. The use of energy efficient technology is on the rise, especially within industrial automation, and imbalanced energy systems is a major target of improvement within industrial automation. VINCER‘s electric actuated ball valves provide both excellent energy savings and a substantial reduction of energy costs within operational systems, making them an eco-friendlier option.

Enhanced Protection

Every industry has its risks, but safety measures are crucial when working in oil and gas, chemicals, and power generation. Electric actuated ball valves help reduce safety concerns by enabling remote control of valves. This remote control feature enables a reduction in the number of operators working close to hazardous sites. Electric actuators are also included in several emergency shut down systems which provide further control over safety concerns.

Main Applications of Automations for Electrically Operated Ball Valves

From fluid control to advanced automation, electrically operated ball valves serve a wide range of functions. Their design versatility to accommodate various industries also expands their range of applications.

The Chemical and Petrochemical Industries

Gas and chemical flow routes are complex. Frameworks of pipelines are automation directed for the cost effective transport of the gas and chemical, which improves operational efficiency and seamless system integration.

Water Treatment Plants

Water treatment plants automate the control and monitoring of the treatment process and use electrically actuated ball valves for the control and treatment of the different filtration and processes step in the treatment cycle. Each stage of the treatment process uses control valves to efficiently manage the flow volume and control the quality of the treatment process to optimize the response time for treatment control and quality adjustments.

Oil and Gas Industry

Electrically actuated ball valves control the flow of oil and gas in pipelines, processing plants and drilling rigs in the oil and gas industry. Ball valves and other actuated flow control equipment is designed for the industry’s high pressures and tough conditions. Automated, remote flow control reduces safety risks by minimizing manual intervention. VINCER is known for reliable electric actuated ball valves built for the oil and gas industry.

HVAC Systems

In the HVAC industry, electric actuated ball valves ensure the effective regulation of the system’s air, water, and refrigerant flow. In commercial and industrial HVAC systems, these valves perform critical functions for the optimal control of system temperatures. Nevertheless, they aid system efficiency and energy expenditure optimally and economically.

The Rise in Popularity of Electric Actuated Ball Valves

The rise in popularity of electrically actuated ball valves can be attributed to the increasing demand for automation, energy efficiency, precision, and enhanced control of system elements. Given the advantages offered by these valves over manual and pneumatic systems, their adoption across different sectors has skyrocketed. Companies like VINCER are leading the charge in this industry.

Incorporation with Industrial Control Systems

One of the most important advantages of Industry 4.0 and smart manufacturing technologies is the incorporation of electric actuated ball valves into advanced control systems. Such integration automates the seamless capturing, tracking, and performing remote supervision of the real-time data. Automated systems using these valves partake in real-time data capture, remote supervision, and automation control of the systems. The seamless incorporation of these valves into existing automation systems provides industries with the means to automate systems enhancing automation of the complete system.

Cost Savings & Emphasis on Sustainability

Sustainability, coupled with cost-saving and energy efficiency, are the primary focus of automated industrial systems. In modern raised automated systems, energy efficiency, and sustainability are exhibited most optimally. This is one of the most dominant positive trends of automated systems, manufacturing, and industrial operations, and improved automation raised systems with focus on system sustainability. The electric actuated ball valves by VINCER manufactured for improved energy efficiency are perfect for the growing need for sustainable industrial automation systems.

The Future of Electric Actuated Ball Valves in Industrial Automation

You cannot doubt that the demand for industrial automation will eventually lead to greater demand for electric actuated ball valves. Smart automated systems, especially those integrated with advanced automation systems for valves, become more energy-efficient. The projected value of these energy-efficient systems will become more valuable with the sustainability factors impacting industrial automation. The extent of automation increase will stem from the integration of modern workflow design, remote access, and monitoring within the automation systems.

The need for precise, dependable, and energy-efficient solutions drives the demand for electric actuated ball valves within industrial automation. Automation of workflows and processes enhances safety, reduces maintenance, and improves overall efficiency. With relentless progress in industrial automation, electric actuated ball valves will remain a key component for supporting the desired growth in productivity and the improved sustainability goals that companies like VINCER are dedicated to.