Advantages of 5 Axis CNC Service in Modern Manufacturing

Introduction

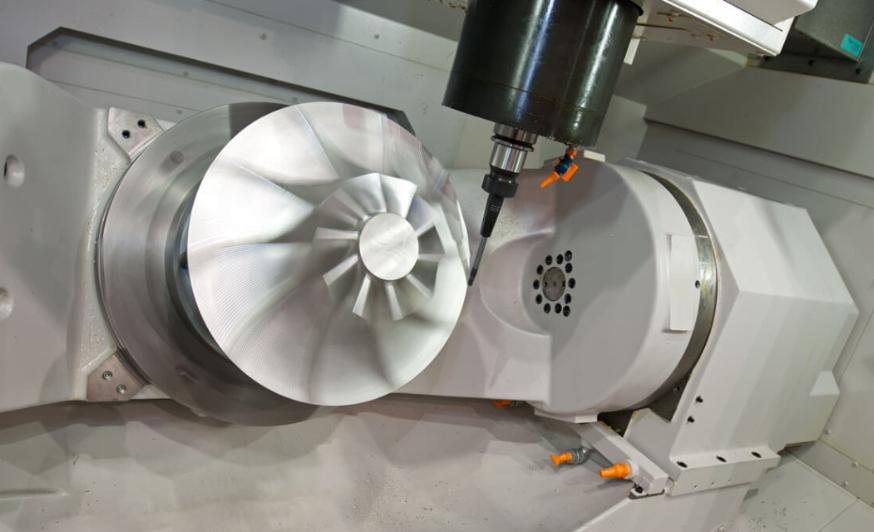

Manufacturing industries are constantly evolving to meet the demands of precision, speed, and flexibility. Among the technologies driving this change, 5 axis cnc service stands out for its ability to produce highly complex components with unmatched accuracy. Unlike traditional 3-axis machining, 5-axis systems allow the cutting tool to move along five different axes simultaneously. This capability enables manufacturers to create intricate parts efficiently while minimizing errors and reducing production time.

From aerospace and automotive to medical and industrial applications, 5 axis cnc service plays a critical role in shaping modern manufacturing practices. Its ability to handle complicated geometries and maintain tight tolerances makes it indispensable in high-precision production environments.

How 5 Axis CNC Service Works

The technology behind 5 axis cnc service involves the movement of the cutting tool along three linear axes—X, Y, and Z—and two rotational axes—A and B. This combination allows the tool to approach the workpiece from virtually any angle, facilitating the machining of complex shapes in a single setup.

By reducing the need for multiple setups, manufacturers can save time and improve part accuracy. The precise control over tool orientation also enhances surface finish and reduces the risk of defects. Advanced software programs generate tool paths that optimize cutting strategies, ensuring maximum efficiency and minimal material waste.

Key Benefits of 5 Axis CNC Service

Improved Precision

One of the most significant advantages of 5 axis cnc service is its ability to maintain precise cutting angles throughout the machining process. This results in components that meet strict dimensional tolerances, which is particularly important for industries such as aerospace and medical devices.

Increased Efficiency

By allowing multiple faces of a part to be machined in a single setup, 5 axis cnc service reduces production time and labor costs. Fewer setups mean less handling of the workpiece and reduced risk of alignment errors, resulting in faster turnaround times.

Greater Design Flexibility

The additional axes provide the ability to machine complex geometries, including curved surfaces, undercuts, and angled features. This flexibility enables manufacturers to produce parts that would be difficult or impossible with traditional 3-axis machining.

Enhanced Surface Quality

Optimized tool paths and continuous cutting angles contribute to a smoother surface finish, reducing the need for extensive post-processing. This is particularly valuable for components that require high-quality finishes, such as medical implants or aesthetic automotive parts.

Reduced Tool Wear

Efficient tool movements and controlled cutting angles reduce stress on the tools, prolonging their operational life. This results in consistent quality over long production runs and reduces the frequency of tool replacements.

See also: Revolutionizing Golf Practice with Modern Technology

Applications Across Industries

Aerospace

In the aerospace sector, 5 axis cnc service is used for producing turbine blades, engine components, and structural parts. High precision and complex geometries are essential for ensuring safety, performance, and fuel efficiency.

Automotive

Engine components, transmission parts, and custom vehicle designs benefit from the flexibility of 5 axis cnc service. Manufacturers can create intricate designs while improving part durability and performance.

Medical Devices

Surgical instruments, prosthetic components, and implants require exact tolerances and complex shapes. 5 axis cnc service ensures the production of high-quality medical devices that meet stringent regulatory standards.

Industrial Equipment

Machining of gears, molds, and specialized fixtures in industrial equipment often involves intricate designs. 5 axis cnc service allows manufacturers to produce these components efficiently, maintaining accuracy and reducing production time.

Factors to Consider When Choosing a Provider

Technical Expertise

Selecting a provider with extensive experience in 5 axis machining ensures high-quality results. Skilled operators can manage complex projects and optimize production processes for better outcomes.

Advanced Equipment

Modern 5 axis machines with automatic tool changers, precise motion control, and advanced software capabilities guarantee consistent quality and efficiency.

Quality Control

Providers should implement strict quality assurance measures, including in-process inspections and final verification using precision measuring tools.

Communication and Reliability

Clear communication about specifications, deadlines, and tolerances is essential. Reliable providers maintain production schedules and ensure timely delivery of components.

Future Trends in 5 Axis CNC Service

Integration with Smart Manufacturing

The adoption of Industry 4.0 technologies, such as IoT monitoring, predictive analytics, and real-time process control, enhances the efficiency and reliability of 5 axis cnc service.

Machining of Advanced Materials

5 axis machining is increasingly used to work with high-strength alloys, titanium, and composite materials. This allows manufacturers to produce lightweight yet durable components for aerospace, automotive, and industrial applications.

Sustainable Manufacturing Practices

Modern providers focus on environmentally friendly machining, including energy-efficient operations, waste reduction, and recycling of materials, while maintaining high-quality standards.

Automation and Robotics

Integration with robotic handling systems and automated inspection tools further streamlines production, reducing labor costs and improving repeatability.

Conclusion

5 axis cnc service represents a significant advancement in modern manufacturing. Its ability to produce highly complex components with precision, efficiency, and superior surface quality makes it indispensable across industries. Aerospace, automotive, medical, and industrial sectors all benefit from the technology’s versatility and reliability.

Selecting a provider with technical expertise, advanced equipment, strict quality control, and reliable delivery ensures optimal results. As technologies evolve and new materials are introduced, 5 axis cnc service will continue to play a pivotal role in shaping the future of high-precision manufacturing.