DS200UPSAG1A: Ensuring Equipment Reliability with OEM Spares

In the complex world of industrial automation, the DS200UPSAG1A module serves as a vital component within General Electric’s control systems, powering critical operations across manufacturing facilities worldwide. When this essential part reaches end-of-life status or becomes discontinued, industrial managers face a pressing challenge: how to maintain system integrity without compromising on quality or reliability. The sourcing of authentic OEM spare parts has become increasingly difficult as automation technology evolves rapidly, leaving older yet still-functional systems in need of support. For plant managers, maintenance supervisors, and procurement specialists, equipment downtime translates directly into lost revenue, reduced productivity, and potential safety concerns. The decision between using genuine OEM components versus aftermarket alternatives can mean the difference between seamless operations and costly system failures. This article addresses the critical importance of securing authentic spare parts like the DS200UPSAG1A, explores practical strategies for locating discontinued inventory, and provides actionable guidance for maintaining long-term equipment reliability in an environment where original parts are becoming scarcer.

Understanding the DS200UPSAG1A and Its Role in Industrial Systems

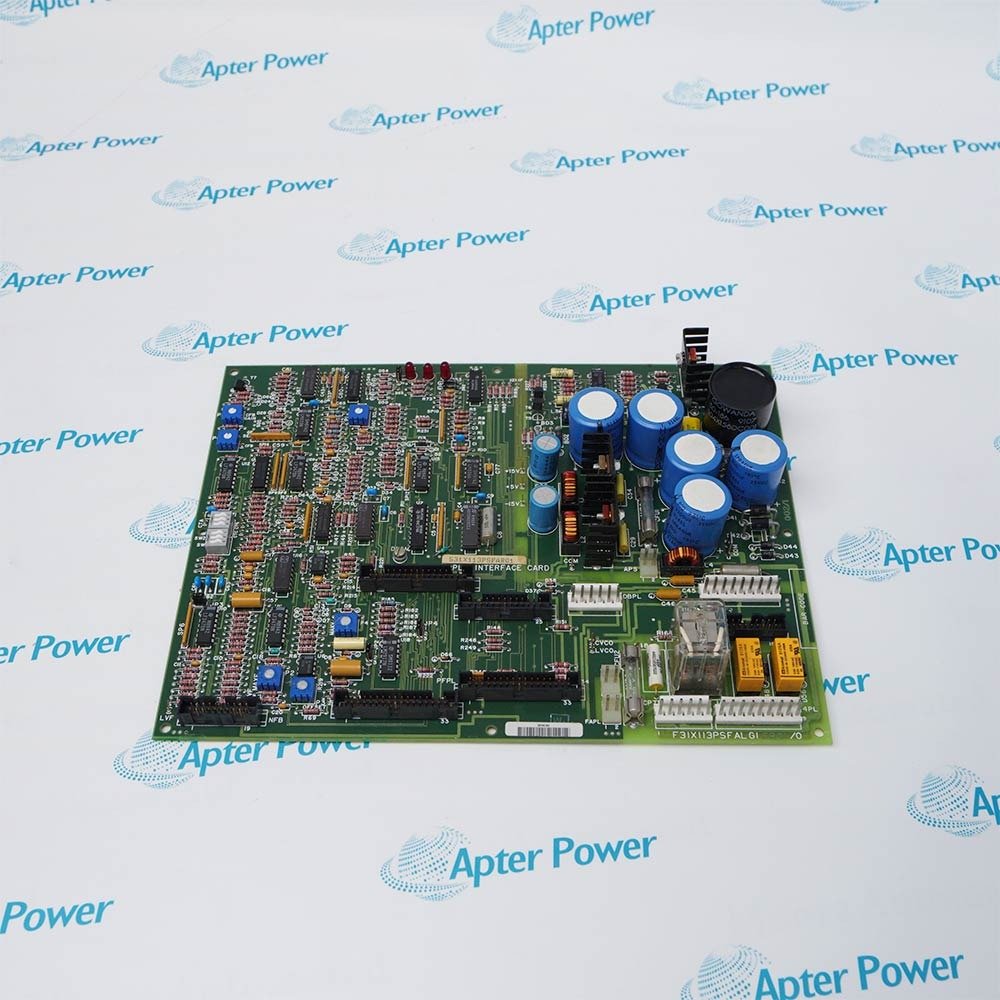

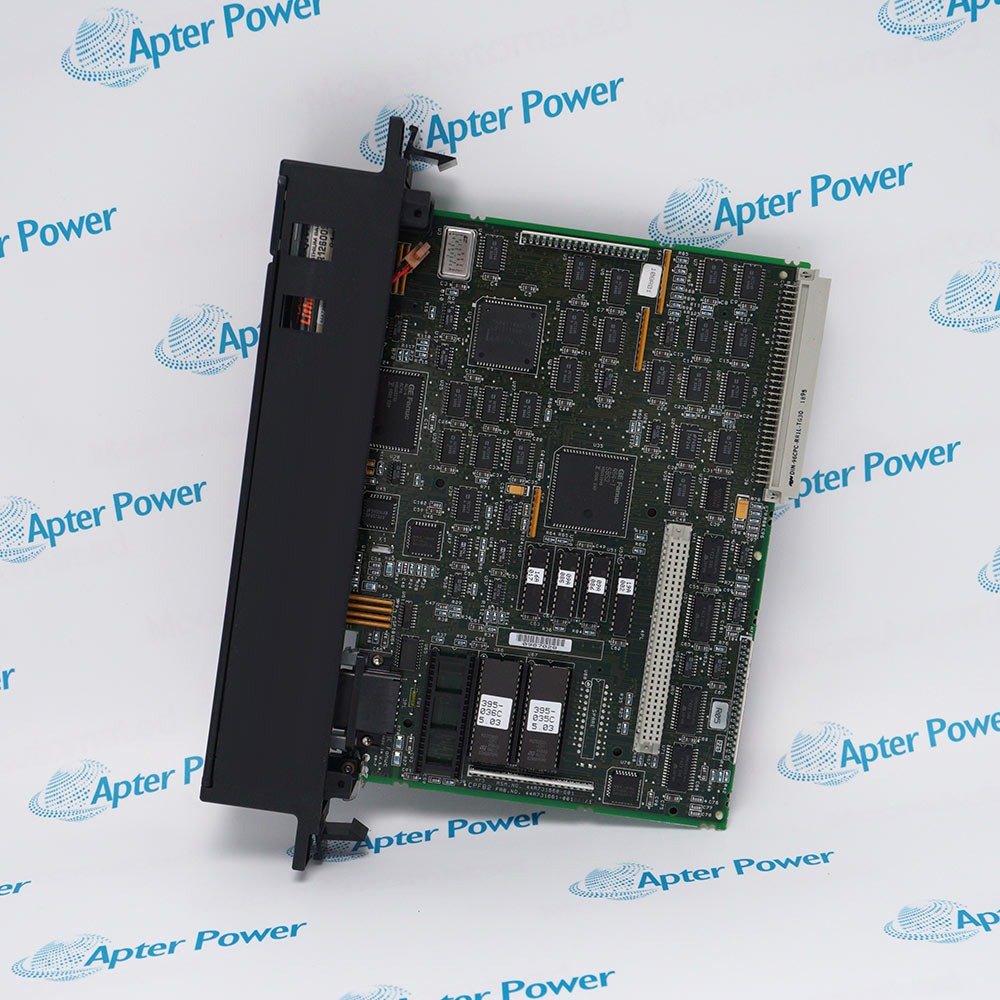

The DS200UPSAG1A functions as a specialized power supply board within General Electric’s Mark V and Mark VI turbine control systems, delivering regulated voltage to critical circuit components that monitor and control gas and steam turbines. This module maintains consistent power distribution across the control architecture, ensuring that sensor inputs, processing units, and output signals remain stable during normal operations and transient conditions. Without proper functioning of this power supply board, control systems experience voltage fluctuations that can trigger false alarms, cause erratic turbine behavior, or lead to complete system shutdowns.

In power generation facilities, petrochemical plants, and manufacturing operations relying on turbine-driven processes, the DS200UPSAG1A directly impacts production continuity. The module’s failure creates immediate operational consequences: turbines may trip offline unexpectedly, automated safety systems might malfunction, and operators lose visibility into critical performance parameters. A single unplanned shutdown in a power generation facility can cost hundreds of thousands of dollars in lost revenue, while manufacturing disruptions create cascading delays throughout production schedules. The component’s position within the control hierarchy means its failure doesn’t just affect one subsystem—it compromises the entire control platform’s ability to maintain safe, efficient turbine operation, making reliable access to replacement parts an essential element of facility maintenance planning.

The Challenge of Sourcing Discontinued Industrial Parts

When General Electric discontinues production of control system components like the DS200UPSAG1A, facilities operating legacy equipment enter a precarious position where replacement parts become increasingly scarce. Original manufacturers typically cease production to focus resources on newer technology platforms, leaving existing installations without direct factory support for components that may still have years of operational life remaining. Authorized distributors exhaust their stock within months of discontinuation announcements, and the secondary market quickly becomes the only viable source for genuine OEM parts. This scarcity creates urgency during equipment failures, forcing maintenance teams to make rushed decisions that may compromise quality standards.

The risks associated with non-OEM alternatives extend beyond simple compatibility concerns. Counterfeit components manufactured without adherence to original specifications may initially appear functional but fail prematurely under operational stress, introducing voltage irregularities that damage connected circuit boards and create intermittent faults that are difficult to diagnose. Aftermarket substitutes, even when produced with good intentions, lack the engineering validation and quality control protocols that ensure reliable performance in demanding industrial environments. These inferior replacements often exhibit different thermal characteristics, altered electrical properties, or substandard component quality that leads to unexpected system behavior.

The financial impact of using non-genuine parts compounds over time. An initial cost savings of several hundred dollars on a replacement module becomes insignificant when weighed against extended downtime from repeat failures, additional labor costs for troubleshooting intermittent issues, and potential damage to expensive connected equipment. Production losses during unplanned outages typically exceed parts costs by orders of magnitude, while safety incidents resulting from control system malfunctions carry legal and reputational consequences that far outweigh any procurement savings from choosing non-OEM alternatives.

Solutions for Locating OEM Spare Parts

Verified Suppliers and Distributors

Identifying reputable sources for discontinued OEM parts requires systematic verification of supplier credentials and inventory authenticity. Begin by requesting documentation that proves the part’s origin—legitimate suppliers maintain records showing the component’s manufacturing date, original packaging, and chain of custody from the OEM or authorized distributors. Ask potential vendors about their quality assurance processes, including how they store components to prevent environmental degradation and whether they provide traceability documentation with each sale. Reputable suppliers willingly share certifications, business references from other industrial clients, and detailed photographs showing manufacturer markings, serial numbers, and packaging condition.

When evaluating suppliers, inquire specifically about warranty terms and return policies, as established vendors stand behind their inventory with guarantees that protect buyers from receiving defective or counterfeit components. Request information about the part’s storage history—components stored in climate-controlled environments with proper electrostatic discharge protection maintain reliability far better than those kept in uncontrolled warehouse conditions. Verify the supplier’s business longevity and industry reputation through online reviews, industry association memberships, and direct conversations with their existing industrial customers who have purchased similar discontinued automation components. Specialized suppliers like Apter Power, which focus specifically on automation and industrial spare parts, often maintain extensive inventories of discontinued components and implement rigorous authentication protocols that protect buyers from counterfeit risks.

Alternative Sourcing Strategies

Certified refurbished parts offer a practical middle ground when new OEM inventory becomes unavailable, provided the refurbishment process follows rigorous standards. Qualified refurbishment vendors disassemble modules completely, replace worn components with OEM-grade parts, test functionality under simulated operational conditions, and provide warranties comparable to new equipment. This approach extends the useful life of existing inventory while maintaining performance standards that match original specifications. When considering refurbished options, verify that the vendor employs technicians trained on GE control systems and uses proper testing equipment to validate electrical characteristics before releasing parts for sale.

Industrial parts marketplaces specializing in automation components aggregate inventory from multiple sources, creating centralized platforms where buyers can compare availability and verify seller credentials. These platforms often implement vetting processes that screen out questionable suppliers, though buyers should still conduct independent verification of part authenticity. Establishing relationships with peer facilities operating similar equipment creates opportunities for parts sharing arrangements—many plants maintain spare inventory that exceeds their actual needs and welcome chances to recover value from surplus components. Industry conferences, technical user groups, and online forums dedicated to specific control system platforms facilitate these connections, allowing maintenance teams to locate hard-to-find parts through professional networks built on shared operational challenges and mutual trust.

Best Practices for Maintaining Equipment Reliability

Establishing a proactive parts replacement schedule prevents emergency situations where critical components fail without available replacements. Document the installation dates and expected service life of all control system modules, then create replacement timelines that account for manufacturer recommendations and actual operating conditions in your facility. Schedule replacements during planned maintenance windows rather than waiting for failures, allowing time to source genuine OEM parts through verified channels without time pressure. Track performance indicators like error rates, voltage stability readings, and temperature measurements that signal component degradation before complete failure occurs. This approach transforms parts management from reactive crisis response into predictable maintenance activities that minimize production disruptions.

An effective inventory management system for critical spares balances the cost of maintaining stock against the risk of extended downtime. Identify components like the DS200UPSAG1A that have long lead times, limited availability, or high failure impact, then maintain on-site inventory sufficient to address likely failure scenarios. Store spare parts in climate-controlled environments with proper electrostatic discharge protection, maintaining original packaging and documentation that proves authenticity. Implement inventory tracking that records purchase dates, supplier information, and storage conditions, rotating stock to use oldest components first while they remain within shelf-life specifications. Periodically audit physical inventory against records to ensure parts remain available when needed and haven’t been borrowed for other applications without documentation.

Training maintenance staff on part identification and verification procedures creates a frontline defense against counterfeit components entering your facility. Teach technicians to recognize authentic manufacturer markings, proper packaging characteristics, and documentation that accompanies genuine OEM parts. Provide reference materials showing common counterfeit indicators like incorrect fonts on labels, missing holograms, or packaging inconsistencies. Establish procurement protocols requiring multiple verification steps before accepting parts into inventory, including visual inspection, documentation review, and supplier credential checks. When staff understand the operational and financial consequences of installing non-genuine components, they become active participants in maintaining equipment reliability rather than passive recipients of whatever parts procurement delivers.

Protecting Your Industrial Operations with Authentic OEM Parts

The DS200UPSAG1A represents more than just a power supply module—it functions as a critical safeguard protecting substantial investments in turbine control infrastructure and ensuring continuous industrial operations. As this component and similar automation parts transition into discontinued status, the imperative to source authentic OEM replacements becomes central to maintaining system reliability and avoiding costly production interruptions. The strategies outlined for locating genuine parts through verified suppliers, leveraging certified refurbished inventory, and building industry networks provide practical pathways for securing components even as original factory channels close. Implementing proactive maintenance schedules, maintaining strategic spare parts inventory, and training staff on authentication procedures transforms parts management from a reactive scramble during emergencies into a controlled process that protects operational continuity. Industrial managers who assess their current spare parts strategy now—identifying critical components, evaluating supplier relationships, and establishing verification protocols—position their facilities to maintain equipment performance regardless of manufacturer support status. The difference between facilities that thrive with aging automation systems and those that struggle with chronic reliability issues often comes down to this fundamental decision: investing in authentic OEM components or accepting the compounding risks of inferior alternatives. Your facility’s operational future depends on making that choice deliberately rather than discovering its consequences during an unplanned shutdown.