The Importance of Slitter Machines in Optimizing Material Usage for Print Jobs

In the contemporary printing and packing environment, optimisation of material plays an important role both economically or sustainably. Over the years, slitter machines have found their place to be a part and parcel of the printing industry as the slitter machine provides a quick and accurate way of getting large rolls of materials to be cut out to smaller widths that are easy to handle. The process is significant to decrease waste, increase the rate of production and overall efficiency of the operations. Through this article we will understand the necessity of slitter machines in optimizing material use in print jobs and how this one is the foundation stone of print modern web converting equipment.

Slitter Machines and Printing Meaning

By learning about our Slitter Machines and how they are useful, we came about understanding the meaning of Slitter Machines and their roles in printing.

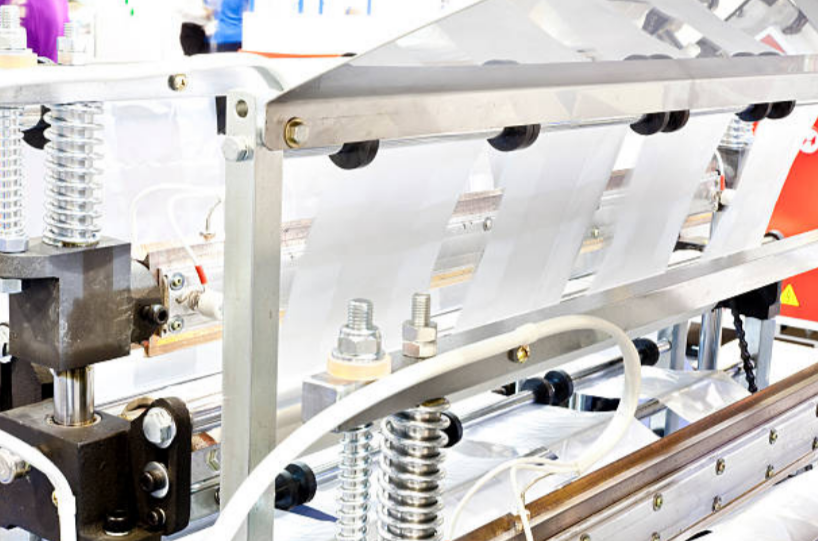

Slitter machine also refers to a specialized machine in web converting equipment that is used to cut, slit, or divide a large roll of material, paper, plastic, films, and textiles into smaller widths. Depending on the application and the material requirements, these are machine different ways, such as, turret slitters as well as rewind slitters. The Splitting process is a crucial process in the packaging and printing departments, as the industry requires exceptional cuts and precision, to attain hoped-for results in printing.

Slitter machines are usually used by inserting a roll of material into the machine where it is torn to strips of predetermined widths on a series of razor-like blades. One can then proceed to further process the material, print it out or package it off depending on the needs of the project. The performance and speed of one slitter machine are important contributors in terms of the quality of the final product since slight differences in the width may cause production problems or cause waste.

Enhancing Material Productivity and Wasting Less

Among the most substantial attributes of the slitter machines in print jobs, one may mention the possibility of optimizing the use of materials. When it comes to large scale printing and packaging during which all the raw material is used, it is important to keep the waste of material at the barest minimum so as to cut down on production costs and increase the profit margin. Slitter machine enables users to cut materials into exact widths in a way such that all the materials can be utilized to the maximum extent. Properly cut into smaller sections, the material enables companies to get most out of the product in each roll and therefore minimize wastage and maximize the material utilization.

In addition, slitter machines are able to minimize off-cuts scrap material, which soon accumulate costs when manufacturing in large quantities. Manufacturers will have the opportunity of ensuring that they utilize the available materials in a very efficient way by adjusting the width of the slits based on the nature of the job and this will save the company a lot of money in terms of cost involving materials consumption. Consequently, companies that introduce the slitter machines into their production will be in a position to increase its bottom-line substantially besides contributing towards sustainable movements through waste reduction.

Increasing the Production Speed and Efficiency of Workflow

Slitter machines are important in speeding and efficiency of production lines. High-volume printing and packaging processes require minimal waste of time and every inefficiency or delay may result in bottlenecks and missed delivery dates. Web converting such as slitter machines has the ability to greatly increase the production rate by automating the cutting process to be able to deal with high lengths of material at a faster time.

Slitter machines have the automation that is used to simplify the workflow, save some manual labor, and accelerate the general production process. In combination with other machines in the printing or the packaging line, the slitter machines would swiftly and accurately generate the availability of the materials required to achieve the printing assignments by reducing downtimes and would optimally be productive. The efficiency created by this leads to reduced lead times and a high potential capacity of being able to undertake more orders which eventually increases the capability of a business to service the customer demand.

Read Also: How Technology Is Revolutionizing Traditional Education

Application of Slitter Machines in Concert with Quality Control

The ability to deliver quality to every print job is one of the challenges that many manufacturers have and slitter machines have been a major contributor to this aspect. The accuracy of slitter machines cuts has a direct effect on the end product. Inferior cutting of materials is likely to give an improper print, uneven seams or packing which may reduce the entire level of quality of the product.

The slitter machines contribute to quality standards of production, as the cuts it brings about are accurate and consistent. This particular tenacity of accuracy is particularly significant when handling resources which may/must be printed on where any irregularity can cause a mis-print or error. Also, web converting machines such as slitter machines, and others aid in making sure that the material being used in the printing process is the right size and shape so that there is a direct smooth finish on the end result.

Conclusion

Slitter machines are also essential tools in optimizing the use of materials in producing print jobs in which it holds considerable advantages to the company in terms of cost efficiency, time savings and quality checking. Slitter machines contribute to ensuring that a business minimizes waste and the amount of material being used by doing so, the company can make the most of their resources, which in the end translates to an increase in profitability and sustainability. Moreover, a capability to raise production rate and guarantee high-quality levels is another strength of these machines which makes them an important component of the contemporary web converting machinery.

In the situation of manufacturers and printers who are aiming to enhance their processes, one increment to higher productivity, lower expenses and increment capacity is investment in a top-notch slitter machine. Their flexibility and accuracy is making the slitter machines more crucial in the printing and packaging market where a thriving competitive market requires precision and speed.