Thread Standards in Industrial Piping: A Comprehensive Overview

Thread standards play a critical role in industrial piping systems, ensuring reliable connections, pressure integrity, and interchangeability across components. From oil and gas to chemical processing and water treatment, properly specified threads are essential for safety, efficiency, and long-term system performance. Understanding the most common thread standards—and where they are applied—helps engineers and procurement professionals make informed decisions.

Why Thread Standards Matter

Thread standards define the geometry, pitch, angle, and sealing mechanism of threaded connections. Without standardized threads, piping systems would suffer from leaks, misalignment, and incompatibility between manufacturers. In industrial environments where high pressure, temperature fluctuations, and corrosive media are common, even minor threading inconsistencies can lead to significant operational failures.

Standardization ensures:

- Interchangeability between components from different suppliers

- Predictable sealing performance

- Simplified maintenance and replacement

- Compliance with safety and regulatory requirements

Common Thread Types in Industrial Piping

Several thread standards are widely used across industries, each with specific characteristics and applications.

National Pipe Thread (NPT)

NPT is one of the most widely used thread standards in North America. It is a tapered thread, meaning the diameter decreases slightly along the length of the thread. This taper creates a mechanical seal when male and female threads are tightened together, often enhanced with thread sealant or PTFE tape.

NPT threads are commonly used in:

- General industrial piping

- Hydraulic and pneumatic systems

- Low- to medium-pressure applications

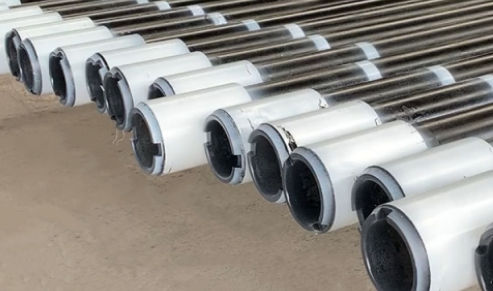

Components such as fittings, couplings, and NPT long nipples are manufactured to precise NPT specifications to ensure consistent engagement and sealing across systems.

National Pipe Taper Fuel (NPTF)

NPTF threads are similar in shape to NPT but are designed to create a “dry seal.” The crest and root interference allows the threads to seal without additional sealant, making them suitable for fuel, gas, and other applications where contamination must be minimized.

British Standard Pipe (BSP)

BSP threads are commonly used in Europe, Asia, and other international markets. They are available in two main forms:

- BSPT (tapered)

- BSPP (parallel)

Unlike NPT, BSP threads have a 55-degree thread angle rather than 60 degrees. This difference means BSP and NPT threads are not interchangeable, despite appearing similar.

Metric Threads

Metric threads are defined by ISO standards and are widely used in global manufacturing. These threads are straight (parallel) and rely on O-rings, gaskets, or washers for sealing rather than thread deformation.

Metric threads are common in:

- Equipment manufactured outside North America

- Precision hydraulic systems

- Applications requiring controlled torque and sealing

Material Considerations and Thread Performance

Thread performance is influenced not only by geometry but also by material selection. Carbon steel, stainless steel, brass, and specialty alloys each behave differently under torque and pressure. Softer materials may deform more easily, while harder materials require tighter machining tolerances.

Proper thread engagement length is also critical. Longer threaded components—such as NPT long nipples—are often used when spacing, alignment, or structural stability is required in a piping run.

Best Practices for Threaded Connections

To ensure reliable threaded joints in industrial piping, consider the following best practices:

- Always match thread standards exactly (e.g., NPT to NPT)

- Use appropriate sealants compatible with the process media

- Avoid over-tightening, which can crack fittings or distort threads

- Inspect threads for damage, burrs, or contamination before assembly

- Follow manufacturer torque recommendations

Conclusion

Thread standards are a foundational element of industrial piping design. From NPT and NPTF to BSP and metric threads, each standard serves specific applications and regions. Understanding their differences helps prevent leaks, reduces downtime, and ensures system compatibility. By selecting the correct thread type, material, and engagement length, engineers can build piping systems that are safe, efficient, and durable over their entire service life.