Vision Systems in Manufacturing: Revolutionizing Automation Processes

In the rapidly evolving landscape of manufacturing, the integration of advanced technologies is paramount to maintaining competitiveness and efficiency. Among these technologies, vision systems have emerged as a pivotal component in automating production processes. These systems, which utilize cameras and image processing software, enable machines to “see” and interpret their environment, leading to enhanced precision, quality control, and operational efficiency. As industries strive to meet the demands of modern production, the adoption of vision systems is becoming increasingly essential. This article delves into the application of vision systems in manufacturing automation, exploring their benefits, challenges, and future potential.

Zastosowanie systemów wizyjnych w automatyzacji procesów produkcyjnych

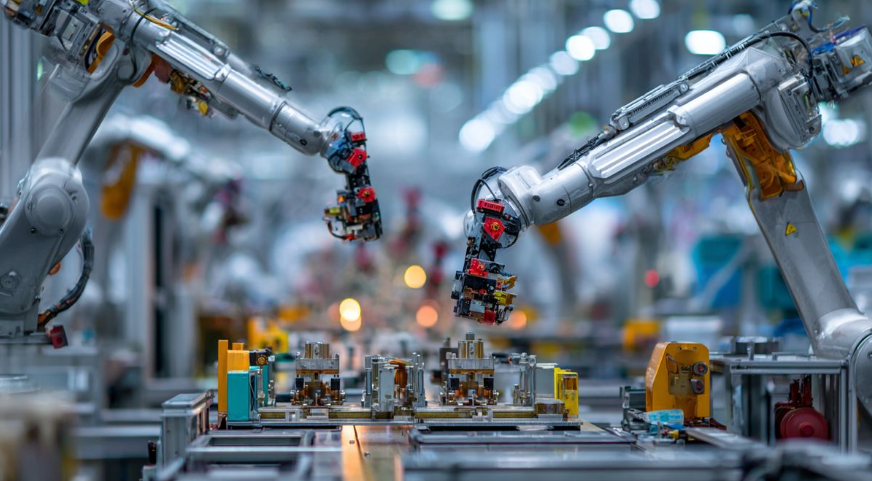

Vision systems are integral to the automation of manufacturing processes, offering a range of applications that enhance productivity and quality. These systems are employed in various stages of production, from initial material inspection to final product verification. By utilizing vision systems, manufacturers can achieve higher accuracy in defect detection, ensuring that only products meeting stringent quality standards reach the market. This capability is particularly crucial in industries such as automotive, electronics, and pharmaceuticals, where precision is non-negotiable.

One of the primary applications of vision systems is in the realm of quality control. Automated inspection processes powered by vision systems can identify defects that are often missed by human inspectors, such as micro-cracks, surface blemishes, or dimensional inaccuracies. This not only reduces the likelihood of defective products reaching consumers but also minimizes waste and rework costs. Furthermore, vision systems facilitate real-time monitoring and data collection, enabling manufacturers to quickly identify and rectify process inefficiencies.

Beyond quality control, vision systems are also pivotal in guiding robotic systems. In assembly lines, for instance, vision-guided robots can accurately position components, reducing assembly time and improving consistency. This is particularly beneficial in high-volume production environments where speed and precision are critical. Additionally, vision systems can be integrated with other technologies, such as artificial intelligence and machine learning, to enhance their decision-making capabilities and adaptability to complex manufacturing scenarios.

Challenges and Considerations in Implementing Vision Systems

Despite their numerous advantages, the implementation of vision systems in manufacturing is not without challenges. One of the primary hurdles is the initial cost of installation and integration. Vision systems require sophisticated hardware and software, which can be a significant investment for manufacturers, particularly small and medium-sized enterprises. However, the long-term benefits in terms of efficiency and quality often justify the initial expenditure.

Another challenge is the complexity of system integration. Vision systems must be seamlessly integrated with existing manufacturing processes and equipment, which can be technically demanding. This requires a thorough understanding of both the vision technology and the specific manufacturing environment. Additionally, ongoing maintenance and calibration are essential to ensure the accuracy and reliability of the systems, necessitating skilled personnel and resources.

Manufacturers must also consider the potential for data overload. Vision systems generate vast amounts of data, which can be overwhelming if not managed effectively. Implementing robust data management and analysis tools is crucial to harness the full potential of the information collected, enabling informed decision-making and process optimization.

See also: How Technology Is Revolutionizing Traditional Education

The Future of Vision Systems in Manufacturing

As technology continues to advance, the future of vision systems in manufacturing looks promising. Emerging trends such as the Internet of Things (IoT) and Industry 4.0 are driving the development of more sophisticated and interconnected vision systems. These systems are expected to become even more intelligent, capable of autonomous decision-making and self-optimization.

The integration of artificial intelligence and machine learning with vision systems is set to revolutionize manufacturing processes. These technologies will enable vision systems to learn from data, improving their accuracy and adaptability over time. This will lead to more efficient production lines, reduced downtime, and enhanced product quality.

Furthermore, advancements in sensor technology and image processing algorithms will expand the capabilities of vision systems, allowing them to operate in more challenging environments and perform increasingly complex tasks. As a result, vision systems will play a crucial role in the evolution of smart factories, where automation and data-driven decision-making are at the forefront of production.

In conclusion, vision systems are transforming the manufacturing landscape by enhancing automation, improving quality control, and driving efficiency. While challenges remain, the potential benefits and future advancements make them an indispensable tool for modern manufacturers striving to stay competitive in a rapidly changing industry.